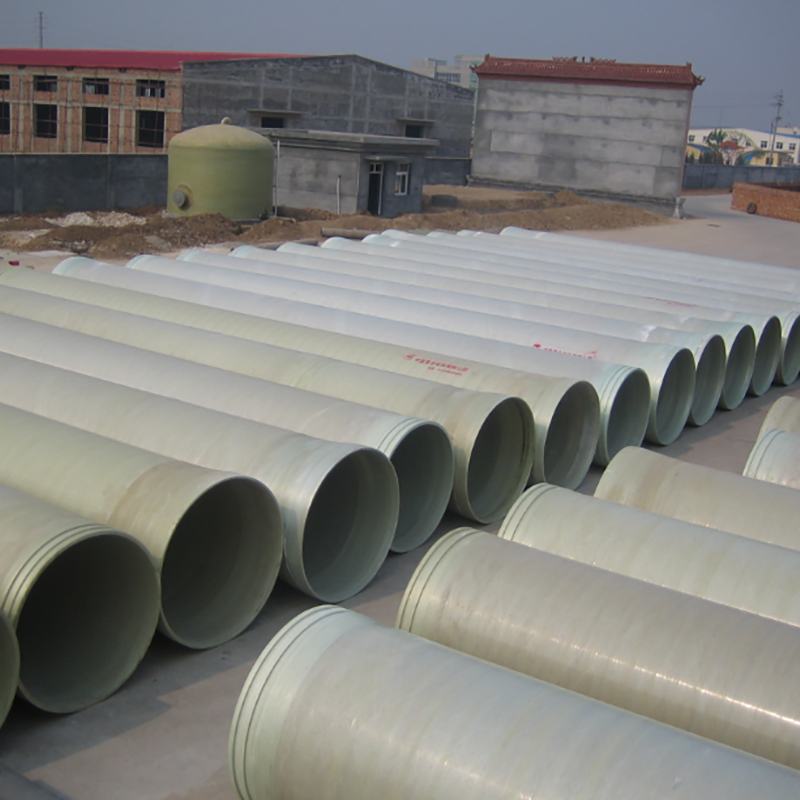

Mechanical wound fiberglass pipes are lightweight, high-strength, and corrosion-resistant non-metallic pipes. It is made by a special process using resin as the matrix and glass fiber as the reinforcing material. This type of pipeline has advantages such as corrosion resistance, leakage resistance, and thermal insulation, as well as lightweight, high-strength, long service life, strong designability, low fluid resistance, convenient installation, and low overall cost. It can be widely used in industries such as petroleum, chemical, pharmaceutical, power, paper-making, urban water supply and drainage, factory sewage treatment, seawater desalination, gas transportation, mining, etc. It is an ideal pipeline for transporting liquids and gases. In recent years, the production of fiberglass pipes in China has developed rapidly, with an increasing quantity and a wider range of applications and departments.

Fiberglass reinforced plastic sand pipes with fiber winding have reliability, safety, and economy. They are mainly used for buried pipelines and long-distance pipelines. They have the characteristics of light weight, high strength, corrosion resistance, long service life, low operation and maintenance costs, and can save a lot of funds for construction projects.

1. Lightweight and high-strength: The specific gravity of fiberglass sand filled pipes is 1.65-2.0. For the unit length weight of the same pipe diameter, it is only 1/3 of carbon steel, 1/5 of cast iron pipe for FRP pipe, and 1/10 of prestressed concrete pipe. This reduces lifting costs and improves installation speed during construction.

2. Good Hydraulics characteristics: this characteristic is particularly prominent in the field of water supply and drainage, and its hydraulic characteristics are good.

(1) It can save on pipeline pumping costs. (2) Reduce the size of the pipe diameter. (3) Shorten pumping time.

(4) FRP pipes do not scale during long-term water transportation and do not require cleaning, ensuring that the water quality is not subject to secondary pollution.

3. Good water resistance and corrosion resistance: The corrosion resistance of fiberglass sand filled pipes is excellent, reducing anti-corrosion costs and extending service life; At the same time, due to its non rusting properties, the water quality of the transmission system is not subject to secondary pollution. It can also be used to transport media such as sewage, mud, seawater, etc.

4. Pressure resistance: Design and manufacture pipes and fittings according to the pressure required by the process, and conduct a water pressure test at 1.5 times the pressure required by the process.

5. The interface has good sealing performance, no leakage, no rupture, and increases the safety and reliability of water supply.

6. Non toxic, can be used to transport drinking water.

◆ Drinking water transmission main and distribution pipes

◆ Sewage and rainwater pipelines

◆ Agricultural irrigation pipes

Under the control of computer, the inner lining is manufactured on the core mold according to the same process as the filament wound FRP pipe. After curing, the structural layer is wound according to the designed line shape and thickness, and the mortar mixed with quartz sand and resin is wound in the structural layer, and finally the external protective layer is wound.

resin, chopped fibers, continuous glass fibers, and quartz sand.

Diameter: DN100-4000

Pressure rating: 0.1MPa, 0.6MPa, 1.0MPa, 1.6MPa, 2.0MPa, 2.5MPa

Stiffness levels: SN1250, SN2500, SN5000, SN10000.

Length: 6m, 12m